This simple sub floor materials calculator will provide you with the lineal feet of floor joist needed the number of sheaths to cover the floor and how much glue and how many screws it takes to attach the sheathing to the joist.

How many nails per sheet of subfloor.

If i end up with a tube or two at the end of the day it wont t get wasted.

570 nails per square.

I calculate a little less 261 per sheet with 2 around perimeter and 6 in field.

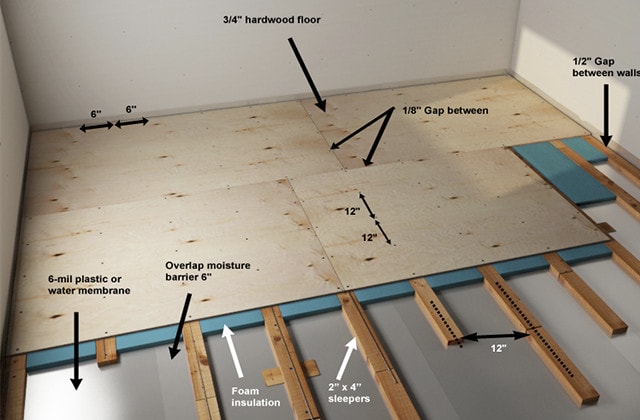

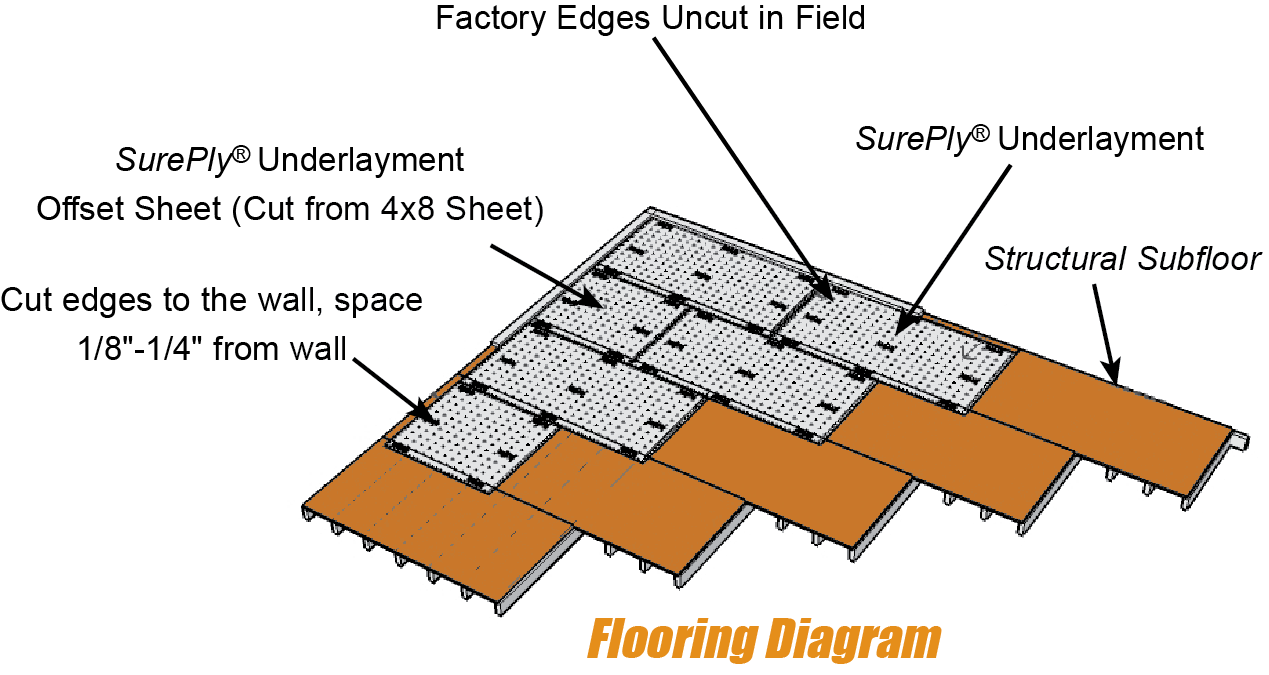

To avoid buckling subfloor panels should be spaced with a 1 8 inch gap at all edges and ends to provide room for naturally occurring expansion.

Tongue and groove edges on many premium floor panels such as weyerhaeuser s edge gold osb panels are designed to self gap.

The screw count is a bit high at times but this will allow for losing some.

Nail spacing for sheets of osb and plywood is 8 inches per nail.

Use 6d common nails spaced 6 apart on edges and 12 apart in the field.

Provide a 1 8 inch gap.

Screws need to be twisted into the subfloor which takes more time than simply shooting a nail into subfloor material.

Liquid nails subfloor deck construction adhesive ln 602 lnp 602 is a specially formulated weatherproof grade adhesive for interior and exterior construction offering easy cold weather gunning ability.

According to table r602 3 1 of international residential code irc subfloor fastener schedule is as follows.

Yeah that is about right i just think 4 spacing is better for most underlayment unless you re using the 1 2 crown staples.

4 feet equals 48 inches which you then divide by 8 to determine that you ll need six nails where the board comes in contact with a truss.

Shakes and shingles also come in a variety of widths that may also affect the number of nails used per square.

Please be advised that the counts above are approximate and may vary significantly due to the different amount of exposure desired in each job.

1 1 8 1 1 4 panels.

Regardless of firing mode an air nailer lets you drive nails within seconds of each other which saves time compared to using a screw gun.

However some screw guns like the senco duraspin ds440 ac are auto fed.

Lay sheets in rows with the long edge horizontal to the roof bottom.

This means that you ll need to use six nails per each truss that runs under the sheathing because each sheet measures 4 feet wide by 8 feet long.

Use 8d common nails spaced 6 apart on edges and 12 apart in the field.

The minimum osb panel size is 24 inches in any direction and each sheet end must rest on a rafter.

You need 32 feet of bead per sheet and sometimes i put a bead thru the tongue.

Penetrates wet frozen and treated lumber.