Nails for roof sheathing first if you re in a high wind uplift zone and even if you re not if hurricanes really are a concern you should consider yourself in one you ll want to use a modified nailing schedule typically 6 along the edge and in the field using 8d ring shank nails.

How many nails per sheet of plywood on roof.

Go back to the bottom of the sheet and tack it home.

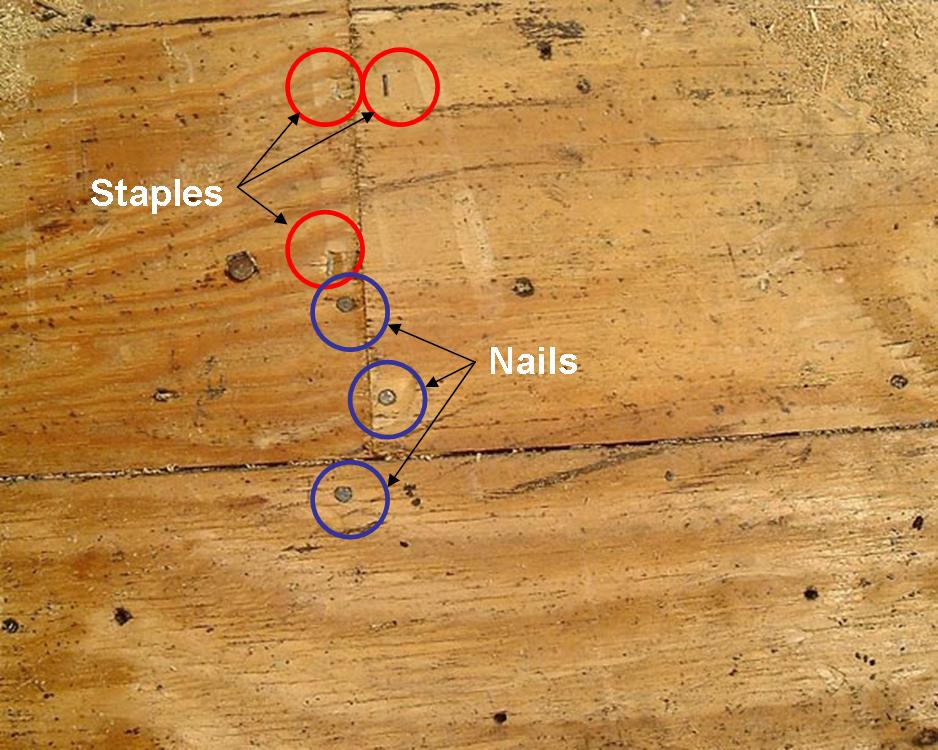

Do not countersink these nails.

Lay sheets in rows with the long edge horizontal to the roof bottom.

Wood shingles 3d 1 1 4 2 28 na.

570 nails per square.

The lengths of nails are dependent upon the medium into which the nail is driven and can be adapted for a variety of.

24 new roof over an old roof.

If 8d common nails are specified the nail diameter must be at least 0 131 inch wider than typical 8d pneumatic nails.

That s 45 nails per sheet of plywood.

Roof material nail length pounds per square coils per square.

8 penny coil nails usually with ring shank and spacing with clips or at least a 10 penny nail.

Comp shingles dimensional 1 1 4 1 63 2 63.

Plywood osb 8d 2 1 2 1 35 na.

Because of plywood s versatility different types of nails are recommended for specific jobs.

This means that you ll need to use six nails per each truss that runs under the sheathing because each sheet measures 4 feet wide by 8 feet long.

Shakes and shingles also come in a variety of widths that may also affect the number of nails used per square.

Technical fact sheet no.

Wood shakes medium 5d 1 3 4 1 75 na.

Many manufacturers recommend that nails be spaced no farther apart than 6 inches on the edge of a sheet.

Nail spacing for sheets of osb and plywood is 8 inches per nail.

12 oc on interior sheet rafters and 6 oc on exterior perimeter rafters of each sheet.

Also nails should be no closer than 3 8 inch from the edge of a panel and driven flush.

There are many uses for plywood from roofing to subfloors and everything in between.

Please be advised that the counts above are approximate and may vary significantly due to the different amount of exposure desired in each job.

Osb plywood 72 nails per sheet.

Depending on the job i will pull my o c measurements as i go or premark the sheet and then tack the top of the sheet at each rafter and drive it home.

Comp shingles smooth 1 1 33 2 63.

Provide a 1 8 inch gap.

4 feet equals 48 inches which you then divide by 8 to determine that you ll need six nails where the board comes in contact with a truss.

Wood shakes heavy s 6d 2 2 50 na.

I follow the code requirements and the spacing and attachment methods listed by the apa american plywood association.

Now you have ten nails in the sheet and it s flush with the rest of them and you go to the next sheet and repeat.