Whenever air temperature at the time of concrete placement is below 4 5 c and freezing temperatures within the first 24 hours after placement are expected high initial temperature shall be established protect concrete during placing consolidating and finishing to avoid delay of setting.

High temperature concrete mix design.

For this initial set should be recorded at a minimum of once per month per mix design to verify when the heat and or steam can be introduced.

If heat or steam is used to assist in curing initial set should be achieved prior to the introduction of heat and or steam.

Use a low aggregate cement ratio.

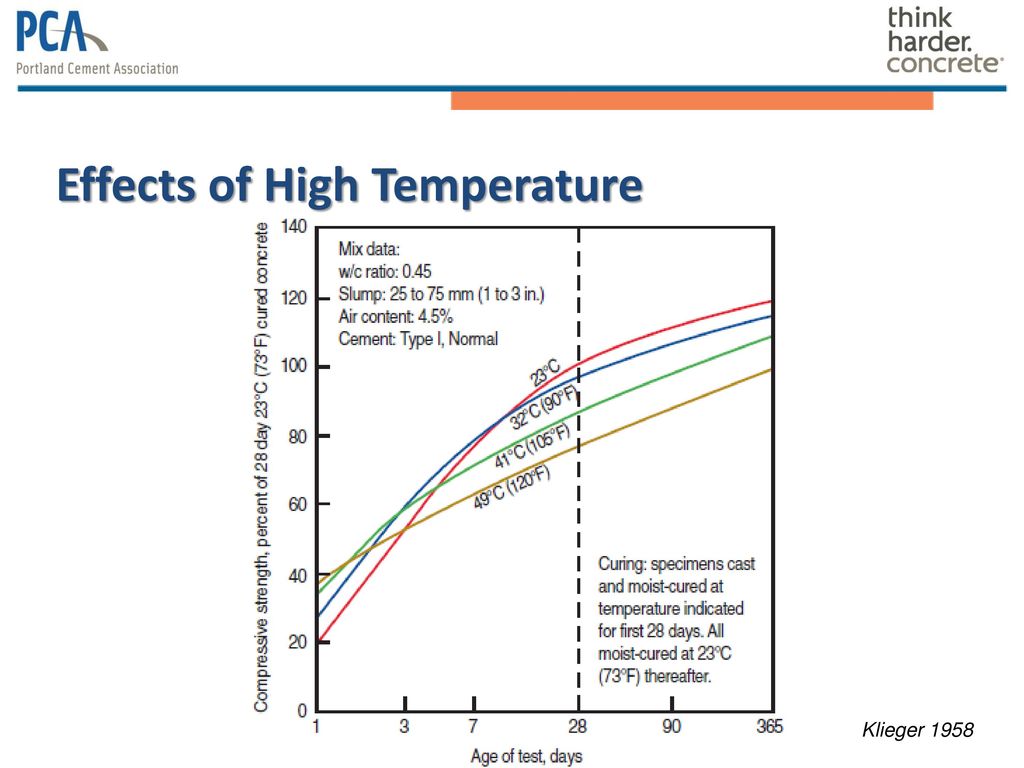

Heat differences in materials.

High curing temperatures can also be controlled when mass pouring with cooling pipes.

This process is usually adopted for structures which requires higher grades of concrete such as m25 and above and large construction projects where quantity of concrete consumption is huge.

Fresh concrete temperature at the time of placing should be between 45 and 90 f.

Sakrete high heat mortar is a dry medium duty mortar ideal for setting masonry units in fireplaces fire pits or chimney applications such as setting.

The temperature when the concrete is placed can be somewhat controlled by using cold water for the mix cooling down aggregates using ice or pouring at night when temperatures are naturally lower.

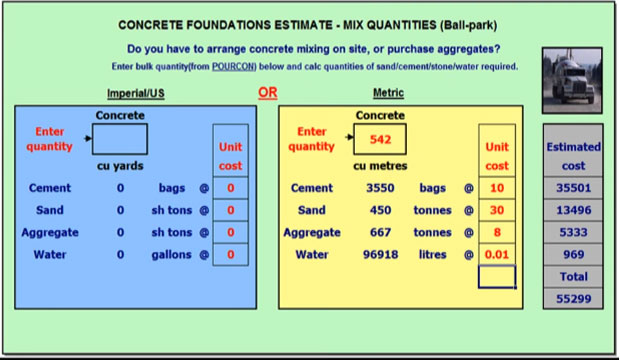

Concrete hub s concrete mix design tool.

To sum up if designers of a concrete mix wishes to achieve a high degree of fire endurance in the concrete itself without going to the use of special refractory materials they should heed the following advice.

Fireproof concrete has several applications for homeowner s and industry.

The concrete mix design involves various steps calculations and laboratory testing to find right mix proportions.

The concrete hub app now provides an easy fast and free way to perform a preliminary mix design.

How to make heat resistant concrete type for buildig wood fired pizza ovens and similar applications where heat and heating is present.

Refractory concrete mixture ingredients recipe for mixing by hand and concrete in building pizza ovens.

Many wood fired ovens kilns and fireplaces are built with fireproof concrete or other fireproof material known as refractory concrete.

All concrete mixes possess unique properties the design process can be time consuming and challenging.

However with careful design and construction such situations can be avoided.

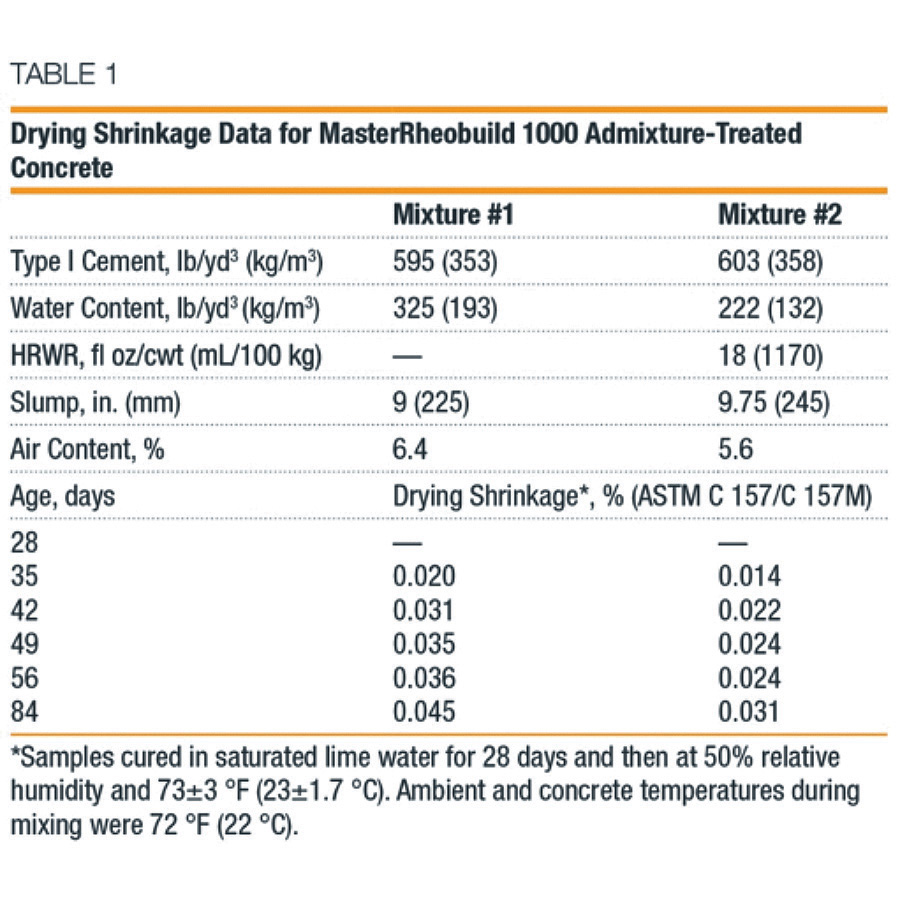

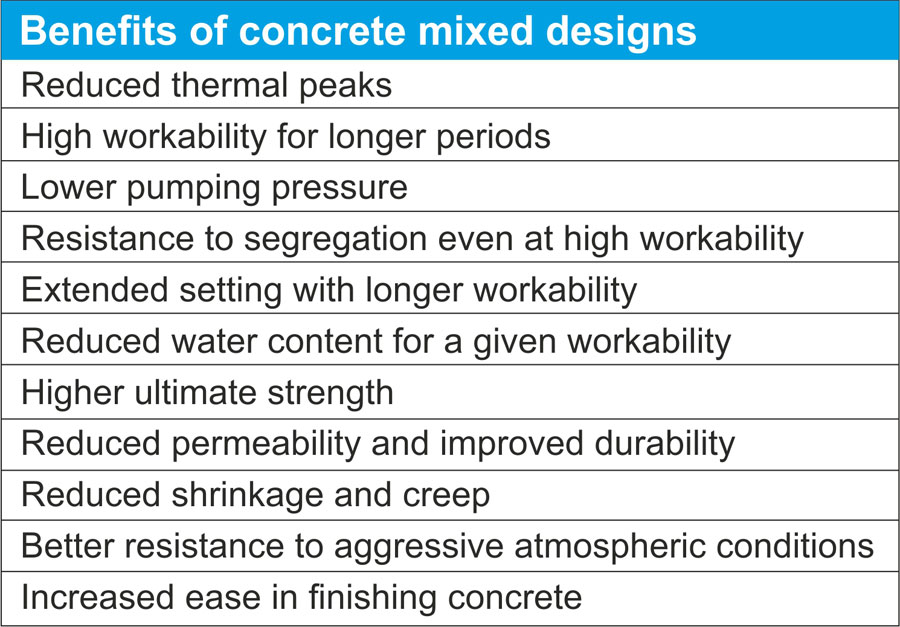

Present paper enlists and recommends various prevention measures which should be incorporated while designing a concrete mix to be used for structural elements which will be subjected to high temperature exposure thus causing damage during its design life.

Of the aggregate available use the one that exhibits the greatest stability at high temperatures.

The concrete hub app however solves these challenges associated with creating a unique concrete mix.